From Light to Heavy, Basic to Bold.

At Pioneer Denim, every fabric tells a story — of craftsmanship, performance, and creative freedom. We offer a complete denim solution, from featherlight 2.5 oz to rugged 22 oz, all made with precision and care using advanced dyeing and weaving technologies. We have a wide variety of indigo, black and colour shades, which can be applied on every fabric construction or composition.

The Fabrics

-

Rigid cotton

100% cotton fabrics from 2,5-22oz in conventional, BCI, GOTS, OCS, GRS or Regenerative cotton.

-

Comfort stretch

From 7-13oz with 1-2% elasthanse to achieve the perfect quality comfort for your jeans and apparel.

-

Super stretch

Soft and very stretchy fabrics are created with a blend of elastane and T400 polyester to create the ultimate comfort and skinny look.

-

Blended fabrics

Cotton is blended with Tencel, linen, hemp, pineapple, wool, silk, jute to create distinctive looks, special hand-feel and less impact on nature.

-

Stripe fabrics

A wide variety of yarn-dye and structured stripes to show a special look being authentic or high fashion.

-

Dobby fabrics

Weaves on special dobby weaving machines creating specific structures like herringbone, checks, jacquards and patterns.

-

Overdye fabrics

Ready for dye fabrics, in a wide variety of compositions, create colour denim, chinos, workwear, army or high fashion garments.

-

Cotton-less fabrics

Fabrics woven without virgin cotton to safe impact on the planet. These fabrics consist of fibres like recycled cotton, linen, hemp and Tencel.

The Process

-

Raw materials

Pioneer Denim has a rich history of sourcing quality cotton from all over the world with a wide range of recycled cotton certifications. Besides that Pioneer Denim sources other rich materials like Tencel, wool, silk, linen, etc to blend with cotton in order to create low impact innovations.

-

Spinning

Pioneer Denim has built a great R&D team, with international consultants, who create a 360° approach from open end, ring, dual core and a wide range of innovating blended yarns.

-

Indigo Dyeing

Pioneer Denim has several indigo dying lines including salt free less water dyeing, eco advance dyeing, low impact dyeing, aniline free dyeing and using responsible chemicals.

-

Weaving

Pioneer Denim is weaving the denims in many different weights and constructions on looms like high speed wider width looms, airjet looms, rapier looms and smart shed dobby looms.

-

Finishing

At Pioneer Denim fabrics are finished after weaving the denim fabric include singeing, scouring, bleaching, desizing, mercerizing, sanforizing, and bio-polishing, each designed to accomplish a specific goal.

-

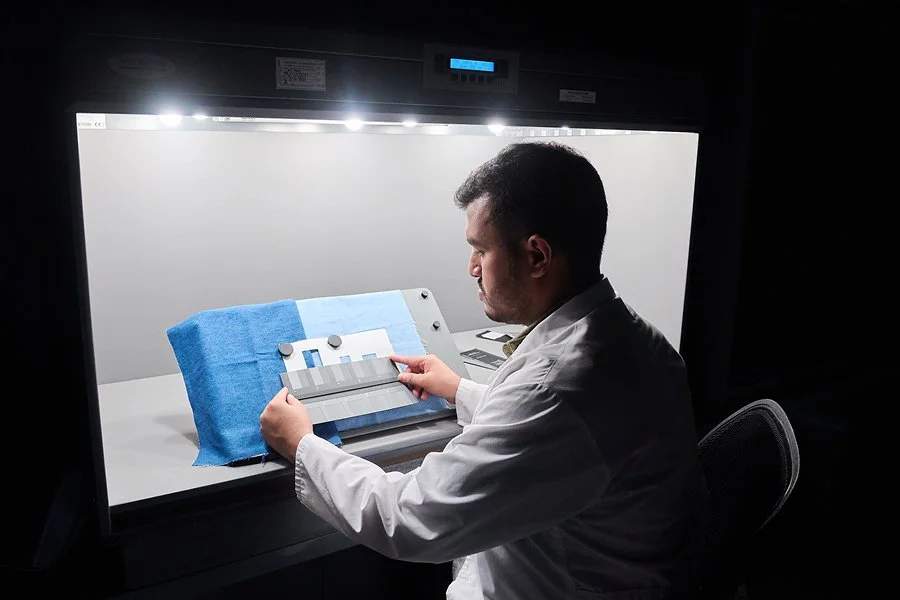

Fabric QC

At Pioneer Denim the fabrics are subdued to a high level of quality control in order to deliver the best consistent quality to our customers.