Where Denim Becomes Fashion.

At Pioneer Denim, we don’t just produce garments—we shape fashion with purpose. From thread to trend, every piece we create begins with responsibly sourced materials and ends with thoughtfully crafted denim that blends innovation, comfort, and conscience. Backed by the legacy of Badsha Group, our garments don’t just follow fashion—they lead it into a more sustainable future.

We pride ourselves on being your one-stop shop for all apparel needs. We specialize in manufacturing a diverse range of high-quality clothing, including:

The Product Range

-

Denim Jackets

-

Denim Shirts

-

Tops

-

Dresses

-

Jeans

-

Pants

-

Shorts

-

Skirts

The process for protos and production

-

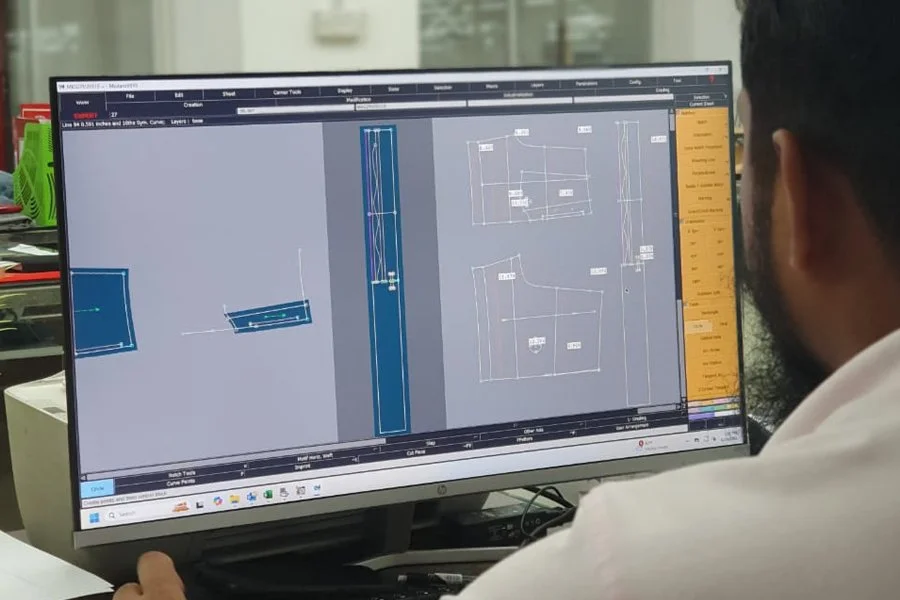

Pattern making

Pioneer Denim has a team who work with the most advanced Lectra systems to create the best fits from basic to fashion.

-

Collection Development

We have an extensive team of merchandisers and developers who develop the designs from proto to approval sample to production.

-

Cutting

Pioneer Denim has the latest generation fabric cutters like the Lectra Vector denim automatic cutting machine.

-

Stitching

At Pioneer Denim, every garment tells a story of innovation, precision, and craftsmanship. In our cutting-edge Automated Sewing Unit, powered by Vibemac, Brother,and Juki, each stitch is a perfect blend of technology and skill. From pockets to hems, every detail is crafted with care and precision, bringing denim to life in a seamless harmony of expertise.

-

Dry process washing

At Pioneer Denim, next to the traditional manual dry processing we harness Jeanologia’s laser technology—a revolutionary clean dry process delivering precise, chemical-free finishes with zero water waste, redefining denim aesthetics while driving our sustainable, future-forward vision.

-

Wet process washing

At Pioneer Denim, our Washing Unit fuses creativity with cutting edge technology using next-gen Tonello machines to drive sustainable garment finishing—each wash telling a story of progress, precision, and purpose. We can supply you with the Environmental Impact Scores so you can be transparent of your washing impact.

-

Finishing

Each garment is finished with care, threads cleaned, ironed, labelled and packed.

-

QC

Consistent quality is our middle name, so we check garment in terms of size, construction, wash and consistency.