Make Blue, Think Green.

As a purpose-driven company, we go beyond the functional aspects of our products. Our commitment to sustainability and innovation makes us the preferred choice for premium brands and retailers worldwide.

As a family-owned business, we operate with care -for our people, your products, and the planet. We pioneer environmentally advanced production by developing innovative materials, integrating cutting-edge technology, and by fostering close collaborations with peers, customers and partners.

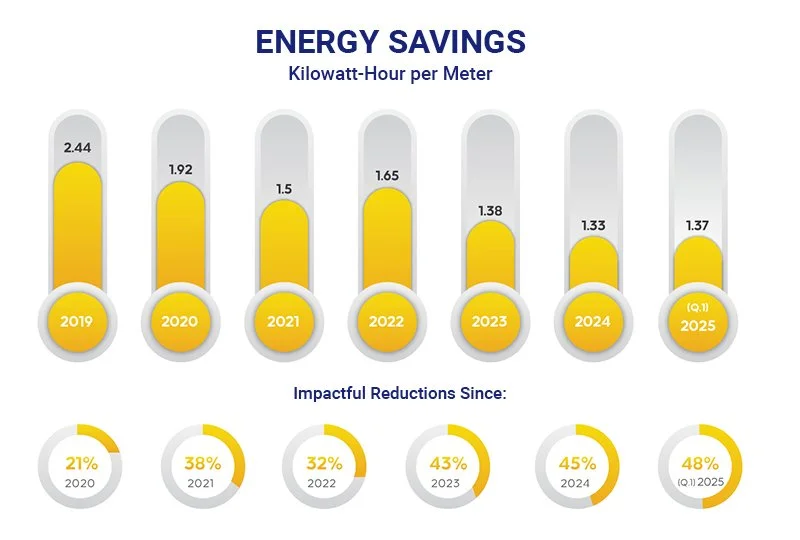

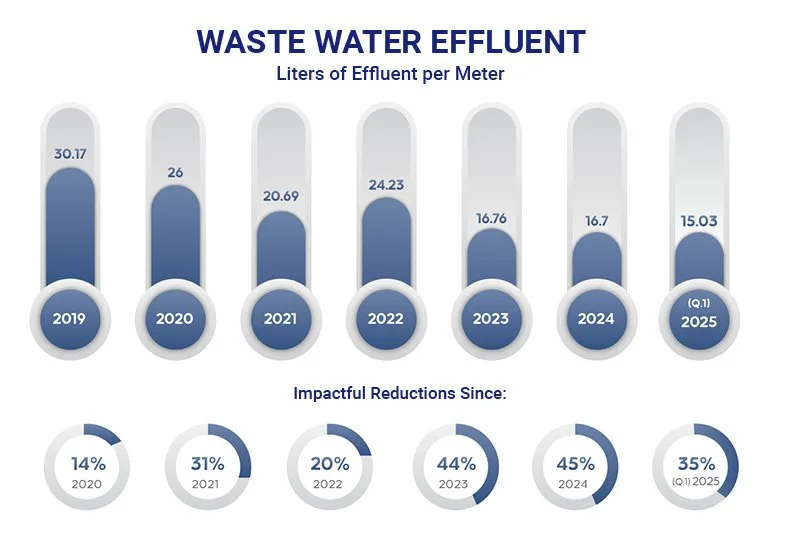

Innovation propels us forward, but sustainability keeps us grounded. We are shaping a future where business growth and environmental stewardship go hand in hand. We continuously reduce our environmental footprint by optimizing water, energy, and steam usage. Initiatives like in-house recycled cotton systems and energy-efficient manufacturing ensure responsible production.

Our pursuit of LEED Platinum Certification reflects our dedication to green manufacturing and sustainable innovation. We lead the textile and RMG sectors through:

Technological Innovation

Embracing advanced machinery and smart manufacturing techniques.

The highest Quality Standards

Delivering products that meet and exceed international benchmarks.

Sustainable Practices

Prioritizing environmental responsibility in every stage of production.

From the first spool of yarn to becoming an industry leader, Pioneer Denim, part of the Badsha Group of Industries, remains committed to shaping the future of textiles, one innovation at a time. We welcome you to read more about our sustainable progress HERE

Think smart. Make responsibly. Work together.

Your Product

We are committed to delivering the best products by maintaining close contact with our clients through an extensive merchandising team. This collaborative approach allows us to achieve the best synergy as partners, and create both qualitative and commercially successful collections, from fiber to fashion in a state of the art fully vertical set up.

At Pioneer Denim, we focus on every detail, from the belief that the finest products come from the best materials, skilled craftsmanship, and innovative production methods. Over the course of nearly 10 years, we’ve evolved from a spinner and fabric mill to a fully vertically integrated company, all while keeping your product at the heart of everything we do.

Our factories are home to expert developers who proactively work to create new, customized products based on your product’s unique requirements. Once sampling or production is complete, our rigorous quality control systems ensure that your product meets the highest standards of consistency and quality, as defined by both our group and your specifications.

A selection of cotton and sustainable fibres which Pioneer Denim can offer:

-

Cotton

-

Organic cotton GOTS/OCS

-

BCI Cotton

-

Regenerative Cotton

-

Recycled Cotton (PIW)

-

Pineapple leaf fiber

-

Tencel by Lenzing

-

Ecovero by Lenzing

-

Linen

-

Hemp

-

Silk

-

Merino

Our People

Ethical Manufacturing:

Our vertically integrated setup provides us with full control over the entire production process, enabling us to implement fair labor practices, ensure safe working conditions, and offer employee welfare programs.

CSR Activities & Facilities:

Pioneer Denim, we prioritize the well-being of our employees and the communities around us. We provide our workers with accommodation facilities and medical care, including insurance coverage. To support a healthy and motivated workforce, we offer spacious recreational areas and organize sports tournaments as well as cultural programs throughout the year.

Beyond our factories, Pioneer Denim actively supports local communities by donating to charitable causes near our manufacturing sites. These include schools, colleges and healthcare organizations. We find it important to invest in education and a healthy lifestyle for future generations.

Social Certificates

-

Sedex

Supplier Ethical Data Exchange is an online reporting platform that helps companies to easily understand their supply chain, collate reports for stakeholders, and work with suppliers to implement improvements to maintain data on ethical & responsible practices and allows them to share this information with their customers.

-

Wrap

Worldwide Responsible Accredited Production is an organization founded to promote safe, lawful, humane and ethical manufacturing around the world and provides the world’s largest independent certification program focused on the apparel, footwear, and sewn products sectors.

The Planet

Sourcing Raw Materials:

Pioneer Denim is supported by its high-quality, integrated spinning sector, specializing in yarn manufacturing in Bangladesh. Since its inception, as part of the Badsha group has gained extensive experience in sourcing and procuring the finest fibers from around the world. This vertical integration enables us to achieve the highest quality yarns, fabrics, and garments with the fastest lead times.

Pioneer Denim sees and strongly increasing demand for sustainable and circular yarns, fabrics and garments, so has really invested in expanding the offer of the best cotton fibers and a wide variety sustainable fibers in our products.

Pioneer Denim collaborates with global leaders in sustainable fibers, such as organic cotton (GOTS/OCS), BCI Cotton, Lenzing fibers, hemp, linen and many other eco-friendly options. Innovation is the driving force behind our vertically integrated success, and we are committed to using the highest quality, environmentally friendly dyes and chemicals in our manufacturing processes.

Pioneer Denim works very close with chemical suppliers like Dystar, Officina39 and Soko.

Other Environmental Efforts

-

LEED

LEED certification for Pioneer Denim plant: Leadership in Energy and Environmental Design is a globally recognized green building certification program that provides a framework for healthy, efficient, carbon and cost-saving green buildings.

Think smart. Make responsibly. Work together.

-

Water Conservation

Pioneer Denim has invested in advanced technologies and machines that minimize water consumption and energy usage throughout the denim manufacturing process, like water recycling plants, zero liquid discharge and rain water harvesting.

-

Energy Conservation

Pioneer Denim in increasing the amount of solar panels on rooftops and developing a biomass boiler installation to increase the usage of renewable energy in the production.

-

Effluent Treatment Plants (ETP)

Pioneer Denim has one of the largest ETP plants in Bangladesh, with a capacity of 6000 m3/per day for the fabric production and 24000 m3/day for the garment production. Operated with biological processing as well as “re-usable” options of membrane and Reverse Osmosis (RO) meaning they re-use treated water at the facility.

-

HIGG Index

Pioneer Denim has achieved 72% in FEM and 87% in SLCP and is also targeting continuous improvements in these scores to become the highest scorer in the industry for producing denim fabrics.

-

Low impact chemicals

Pioneer Denim uses the most sustainable concepts of several suppliers like DyStar®, Officina 39 and Soko. ion goes here

-

Bluesign

Pioneer Denim works with Bluesign for several products. Bluesign is a certification system and a standard for sustainable and safe textile production

-

Circular Economy Initiatives

With our 20 tons/day shredding plant, we recycle PIW/PCW waste, closing the loop and reintroducing recycled materials into the production cycle for a greener future.

-

ZDHC

Pioneer Denim The Zero Discharge of Hazardous Chemicals (ZDHC) Program is a global initiative focused on eliminating hazardous chemicals from the textile, apparel, and footwear industries. Launched in 2011 by a coalition of leading apparel brands, the ZDHC aims to protect both the environment and human health by promoting sustainable chemical management practices across the entire supply chain.